Sheroz Earthworks for Dummies

Sheroz Earthworks for Dummies

Blog Article

The smart Trick of Sheroz Earthworks That Nobody is Discussing

Table of ContentsThe smart Trick of Sheroz Earthworks That Nobody is Talking About4 Simple Techniques For Sheroz EarthworksThe smart Trick of Sheroz Earthworks That Nobody is DiscussingNot known Factual Statements About Sheroz Earthworks Some Known Details About Sheroz Earthworks

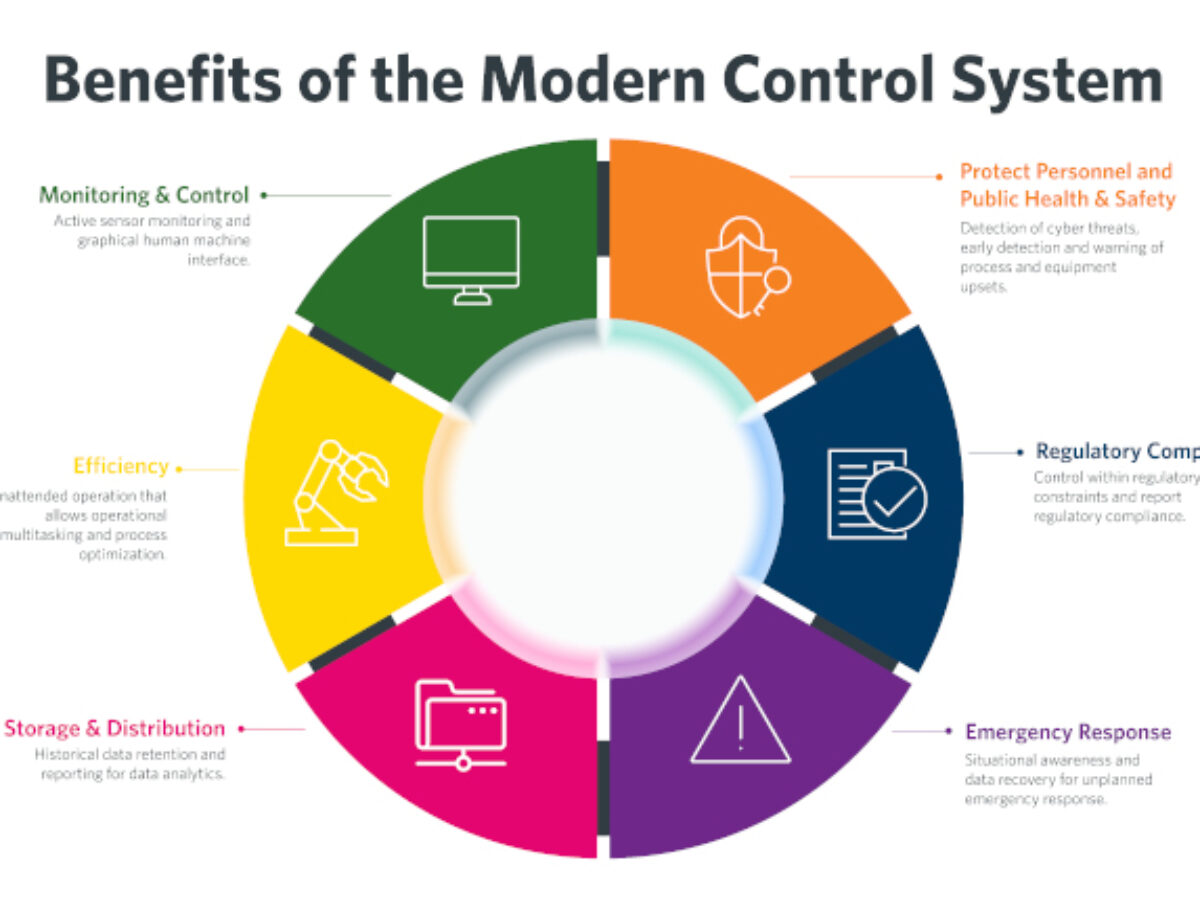

For any earthwork contractor, it is essential to perform work with top quality, precision, and on routine. Using equipment control in work machines makes it possible for maximizing the various phases in the earthwork process, from intending to the maintenance stage - trimble parts. The maker control system helps the equipment driver in acquiring the target airplane rapidly and quickly

The device control system overviews the driver with centimeter accuracy. With Xsite PRO 3D, you'll always understand specifically just how much to reduce or load. Your neighborhood Xsite technological support can direct you and assist with any troubles without going to the site. Remote support saves money and time, as it minimizes downtime in jobsites.

Rumored Buzz on Sheroz Earthworks

Added training and instructions are constantly available over remote support when needed. The earthmoving market has actually used our field-proven options because the early 1990s. Our system's components are thoroughly made to withstand the harsh problems of building and construction websites. Contrast of the same job carried out making use of device control versus the traditional technique discloses that, generally, the conventional method needs 50% even more time to complete the very same task as the technology-assisted technique. https://urlscan.io/result/7bb54d5c-9113-4d9d-b7fe-a8166a06c096/.

Appears good? Enter the Xsite machine control system; it's right here to provide you with a substantial advantage when working with earthmoving equipment. Discover just how Xsite Device Control can improve your performance and make certain job safety and security! We recognize that discovering a brand-new modern technology might seem like a drag, but don't worry! Our friendly and expert regional support solutions have actually got you covered, ensuring that you can maintain functioning smarter without disruptions while on the work! With remote support, your regional Xsite supplier can supply assistance or troubleshooting without having to visit the site! What kind of excavators does machine control fit? Xsite Equipment Control systems can be set up to any type of excavator from mini excavators to big mining excavators.

Just how does machine control work? In 2D systems, the equipment is outfitted with calibrated disposition sensing units. These sensing units are placed on the pre-determined components of the maker in excavators the sensing unit are normally mounted to the framework, boom (or booms), digger arm and to the quick coupler - topcon. By utilizing the information received from these sensing units the system can calculate the precise placement of the excavators pail idea in importance to a recommendation factor.

The system is really simple to find out the fundamentals can be educated in under one hour of training. Just how does the remote assistance work? A wireless web link makes it possible to establish a remote connection between the maker control system and the solution.

Some Known Facts About Sheroz Earthworks.

Xsite Maker Control systems support open conventional data styles, enabling seamless details circulation from one system to an additional. Depending on your option of system (with or without positioning, i.e., 2D or 3D), your Web Site equipment is outfitted with disposition sensing units, a controller system, and a display/operating panel.

Lots of hardware and software solutions exist to aid establish a device's present position on the planet and contrast it with a preferred style surfaceand construction operators can do more to utilize the advantages. Machine control is making use of different positioning sensing units and a display screen to supply the operator with a recommendation between the position of the pail or blade and the target quality.

Depending upon the arrangement, maker control systems can give the driver with a basic visual overview to pail or blade setting, or can instantly move the blade to quality by talking with the device's hydraulics - https://pblc.me/pub/2669cbf4eae9a6. There are maker control systems offered for almost any type of maker: , dozers, excavators, soil and asphalt compactors, scrapers, trimmers, grating makers, and pavers

Not known Incorrect Statements About Sheroz Earthworks

Maker control can also help raise efficiency and decrease total expenses. Building and construction devices without equipment control will end up being a thing of the past and the advantages acquired from it will be various.

Trimble device control systems offer a myriad of benefits to anybody who makes use of earthwork equipment and, at EarthCalc, we can supply you with 3D documents for your machine control-enable equipment. Uncertain if device control is worth the expense? Think about the complying with reasons that you require to consider this alternative.

Using GPS aligned with your 3D style data, these systems practically ensure that you will eliminate or place the proper quantity of material at the building and construction site. On a lot of building sites, revamp is a typical and aggravating truth, but with Trimble equipment control, you can remove the demand for rework.

Examine This Report about Sheroz Earthworks

Frequently, with Trimble equipment control, you can get rid of excess tools at a particular work website. For example, a job that might have called for using 3 or four pieces of digging deep into devices now may need only 2 pieces of devices to accomplish the very same task in much less time. This enables you to move your tools to one more work website and handle multiple tasks at once.

Report this page